Lead content of brass used in plumbing fixtures and devices

Water distribution systems and household plumbing contain numerous brass components. Most such components in service are leaded brass and hence comprise a potential source of Pb in compliance testing under the Lead and Copper Rule. For households, the two components with the greatest potential to affect Pb content of tap samples are faucets and meters.

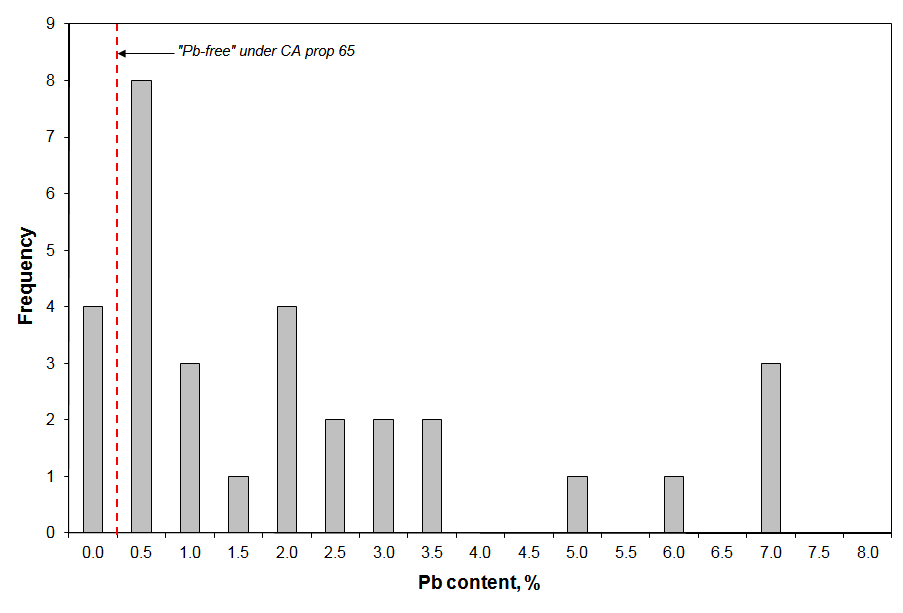

Typical brasses used in these applications are alloys of Cu, Zn, and Pb with small amounts of other metals such as Sn (see List of Additives). The Pb content is typically 2 to 8 %, and these can be marketed as “lead free”. In true no-lead brasses, Bi and Sb are used in place of Pb (http://www.envirobrass.com). The addition of Pb or Bi is made to improve the machinability of the brass.

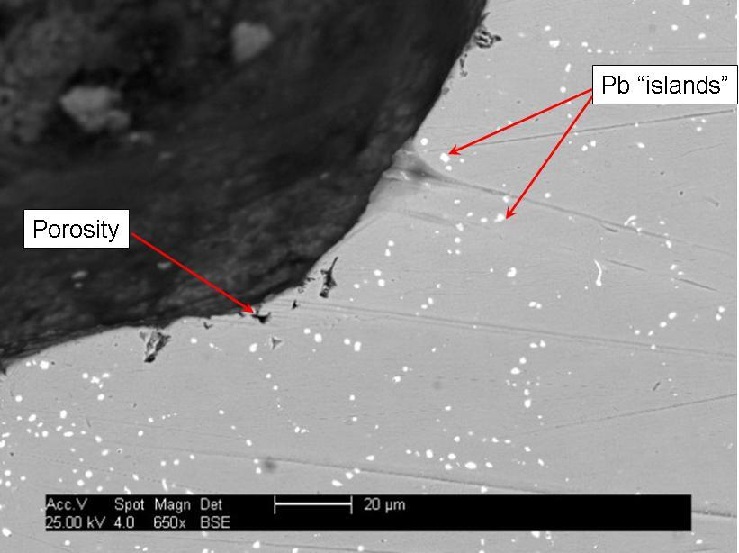

Pb or Bi in brass are present not in solution in the alloy but as discrete blebs or “islands” of pure metal within the alloy. Imaging using Scanning Electron Microscopy reveals this structure (Fig. 1). The image was taken in back-scatter mode, in which the brightness is proportional to the atomic number of the element. The large contrast in mass between Pb and the other elements produces the bright spots. Note also the porous zone at the wetted edge of the brass revealed by the dark areas.

Figure 1. Structure of brass revealed in scanning electron imaging, using back-scattered electrons. Polished section cut through a leaded brass faucet.

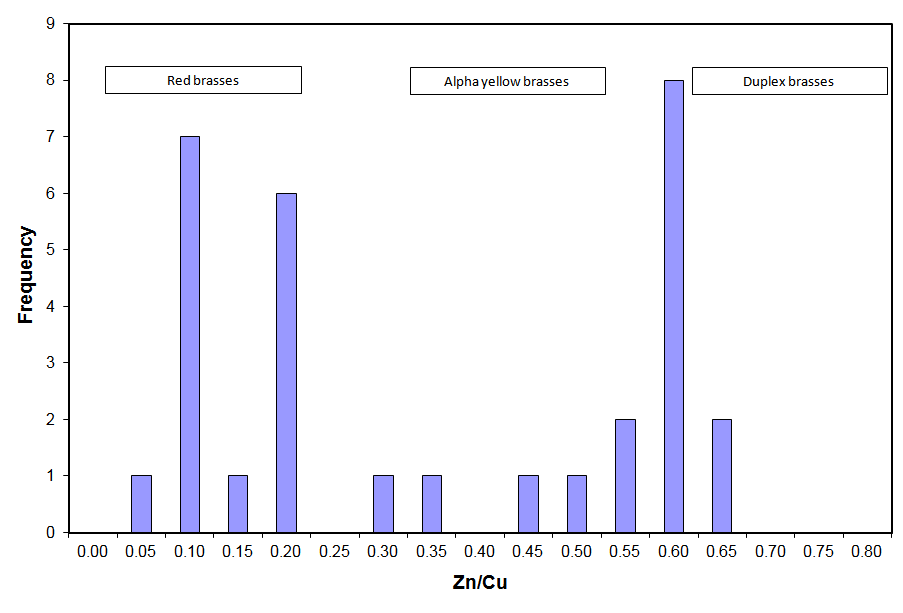

Brass is a highly versatile metal and is manufactured with a wide range of compositions. Table 1 gives compositional data from some brasses used in plumbing components in the US. Note that Pb varies from < 0.25 to about 7 %. The high Sn varieties are “admiralty brasses” and are generally used in marine applications. In the table, the values given are the midpoints of the reported ranges. For analyses totaling greater than 100.1 %, the midpoint Cu and Zn contents were normalized to give 100 % totals.

Figure 2. Range of Pb contents found in commercial brasses (see Table 1).

Figure 2. Range of Zn contents found in commercial brasses (see Table 1).

Selected References to Brass Corrosion

Badawy, W.A. & Al-Kharafi, F.M., 1998. Corrosion and passivation behaviours of a-brass in oxygen-free and –saturated solutions of different pH. Corrosion Prevention & Control, 45-2: 57-68.

Burzynska, L., 2001. Comparison of the spontaneous and anodic processes during dissolution of brass. Corrosion Science, 43: 1053-1069.

Cardew, P.T., 2006. Development of a convective diffusion model for lead pipe rigs operating in laminar flow. Water Research, 40: 2190-2200.

Dudi, A., Schock, M., Murray, N., & Edwards, M., 1997, Lead leaching from inline brass devices: a critical evaluation of the existing standard. Jour. AWWA, 97-8: 66-78.

Gardels, M. C., & Sorg, T.J., 1989. A Laboratory Study of the Leaching of Lead from Water Faucets. Jour. AWWA, 81-7: 101-113.

Kimbrough, D.E., 2001. Brass Corrosion and the LCR Monitoring Program. Jour. AWWA, 93-2: 81-91.

Kimbrough, D.E., 2007. Brass Corrosion as a source of lead and copper in traditional and all-plastic distribution systems. Jour. AWWA, 99-8: 70-76.

Korshin, G.V., Ferguson, J.F., and Lancaster, A.N., 2000. Influence of natural organic matter on the corrosion of leaded brass in potable water. Corrosion Science, 42: 53-66.

Lytle, D.A. & Shock, M.R., 2000. Impact of stagnation time on metal dissolution from plumbing materials in drinking water. Jour. Water Supply: Research and Technology – Aqua, 49-5: 243-257.

Maas, R.P. & Patch, S.C., 1999. Lead Leaching From In-Service Residential Water Meters: A Laboratory Study. Source (CA Section of AWWA), 100-3: 27-28.

Maas, R.P., Patch, S.C., Morgan, D.M. & Kawaguchi, H., 1997. Lead Leaching From Brass Water Meters Under Pressurized Flow Conditions. Proceedings of the American Water Works Association 1997 Annual Conference, 589-602.

Marshakov, I.K., 2005. Corrosion resistance and dezincing of brasses. Protection of Metals, 41: 2305-210.

Merkel, T.H., Gross, H-J., Werner, W., Dahlke, T., Reicherter, S., Beuchle, G., & Eberle, S.H., 2002. Copper corrosion by-product release in long-term stagnation experiments. Water Research, 36: 1547-1555.

Oliphant, R.J. , & Schock, M.R., 1996. Copper alloys and solder. Chapter 6 in Internal Corrosion of Water Distribution Systems. American Water Works Association Research Foundation/ DVGW Forschungsstelle, Denver CO, p. 269-312.

Paige, J.I. & Covino, B.D., Jr., 1992. Leachability of Lead from Selected Copper-Base Alloys. Corrosion, 48-12: 1040-1046.

Rehan, H.H., Al-Moubarak, N.A., & Al-Rafai, H.A., 2000. A model for prolonged dezincification of α-brasses in 3 % sodium chloride buffer solutions at different pH values. Materials and Corrosion, 52: 677-684.

Samuels, E. R. & Meranger, J.C., 1984. Preliminary Studies on the Leaching of Some Trace Metals from Kitchen Faucets. Water Research, 18-1: 75.

Sastri, V.S., 2005. Dezincification studies of some copper based alloys. Corrosion Engineering, Science & Technology, 40-2: 171-176.

Schock, M.R. & Neff, C.H., 1988. Trace Metal Contamination from Brass Fittings. Jour AWWA, 80-11: 47.

Triantafyllidou, S., and Edwards, Marc, 2007. Critical evaluation of the NSF 61 Section 9 test water for lead. Jour AWWA, 99-9: 133-143.

Valcarce, M.B., de Sánchez, S.R., & Vázquez, M., 2005, Localized attack of copper and brass in tap water : the effect of Pseudomonas. Corrosion Science, 47: 795-809.

Table 1a. Average composition of some commercial brasses used in plumbing- major constituents |

||||||||

|

Cu |

Sb |

Bi |

Pb |

Pb range |

Sn |

Zn |

Zn/Cu |

| C23000 | 84.0 | 0.05 | 15.0 | 0.18 | ||||

| C26000 | 69.9 | 0.07 | 30.0 | 0.43 | ||||

C32000 |

84.9 |

|

|

1.8 |

1.5-2.2 |

|

13.2 |

0.16 |

C33000 |

66.0 |

|

|

0.5 |

0.25-0.7 |

|

33.5 |

0.51 |

C33200 |

66.0 |

|

|

2.0 |

1.5-2.5 |

|

32.0 |

0.48 |

C34000 |

63.5 |

|

|

1.0 |

0.8-1.5 |

|

35.5 |

0.56 |

C34500 |

63.5 |

|

|

2.0 |

1.5-2.5 |

|

34.5 |

0.54 |

C35000 |

61.5 |

|

|

1.1 |

0.8-2.0 |

|

37.4 |

0.61 |

C35300 |

61.5 |

|

|

2.0 |

1.5-2.5 |

|

36.5 |

0.59 |

C35330 |

61.7 |

|

|

2.5 |

1.5-3.5 |

|

35.7 |

0.58 |

C35350 |

61.7 |

|

|

3.2 |

2.0-4.5 |

0.15 |

34.5 |

0.56 |

C36000 |

61.4 |

|

|

3.1 |

2.5-3.7 |

|

35.4 |

0.58 |

C83600 |

84.3 |

0.13 |

|

5.0 |

4.0-6.0 |

5.0 |

5.0 |

0.06 |

C83800 |

83.0 |

0.13 |

|

6.0 |

5.0-7.0 |

3.8 |

6.5 |

0.08 |

C84200 |

79.0 |

0.13 |

|

2.5 |

2.0-3.0 |

5.0 |

12.8 |

0.16 |

C84400 |

80.2 |

0.13 |

|

7.0 |

6.0-8.0 |

3.0 |

9.0 |

0.11 |

C84500 |

77.5 |

0.13 |

|

6.8 |

6.0-7.5 |

3.0 |

11.9 |

0.15 |

C84800 |

75.1 |

0.13 |

|

6.8 |

5.5-7.0 |

2.5 |

14.8 |

0.20 |

C85200 |

72.0 |

0.10 |

|

3.0 |

1.5-3.8 |

1.4 |

23.5 |

0.33 |

C85400 |

67.0 |

|

|

3.0 |

1.5-3.8 |

1.0 |

29.0 |

0.43 |

C85700 |

60.9 |

|

|

1.0 |

0.8-1.5 |

1.0 |

35.9 |

0.59 |

C86400 |

57.6 |

|

|

1.0 |

0.5-1.5 |

1.0 |

37.1 |

0.64 |

C87500 |

81.8 |

|

|

0.0 |

0-0.5 |

|

14.0 |

0.17 |

C87800 |

81.6 |

0.03 |

|

0.0 |

0-0.9 |

0.1 |

13.9 |

0.17 |

C87850 |

75.8 |

0.05 |

|

0.0 |

0-0.1 |

0.2 |

20.8 |

0.28 |

C89510 |

87.0 |

0.13 |

1.0 |

0.1 |

0-0.25 |

5.0 |

5.0 |

0.06 |

C89520 |

86.0 |

0.13 |

1.9 |

0.1 |

0-0.25 |

5.5 |

5.0 |

0.06 |

C89530 |

85.0 |

0.10 |

1.5 |

0.1 |

0-0.25 |

4.7 |

7.9 |

0.09 |

C89535 |

86.5 |

0.10 |

1.4 |

0.1 |

0-0.25 |

3.0 |

7.0 |

0.08 |

C89540 |

61.0 |

|

0.9 |

0.1 |

0-0.25 |

0.6 |

35.0 |

0.57 |

C89550 |

61.0 |

0.03 |

0.9 |

0.1 |

0-0.25 |

0.6 |

35.0 |

0.57 |

C89836 |

88.2 |

0.13 |

2.5 |

0.1 |

0-0.25 |

5.5 |

3.0 |

0.03 |

C89844 |

84.2 |

0.13 |

3.0 |

0.0 |

0-0.20 |

4.0 |

8.0 |

0.09 |

Avg regular brass |

70.8 |

|

0 |

2.67 |

|

2.09 |

24.5 |

0.37 |

Avg envirobrass |

79.9 |

|

1.6 |

0.11 |

|

3.61 |

13.2 |

0.20 |

Table 1a. Average composition of some commercial brasses used in plumbing- minor constituents |

|||||||||

|

Al |

As |

Fe |

Mn |

Ni |

P |

Se |

Si |

S |

| C23000 | 0.05 |

||||||||

| C26000 | 0.05 |

||||||||

C32000 |

|

|

0.05 |

|

0.13 |

|

|

|

|

C33000 |

|

|

0.04 |

|

|

|

|

|

|

C33200 |

|

|

0.04 |

|

|

|

|

|

|

C34000 |

|

|

0.08 |

|

|

|

|

|

|

C34500 |

|

|

0.08 |

|

|

|

|

|

|

C35000 |

|

|

0.08 |

|

|

|

|

|

|

C35300 |

|

|

0.08 |

|

|

|

|

|

|

C35330 |

|

0.13 |

|

|

|

|

|

|

|

C35350 |

|

|

0.20 |

|

0.17 |

0.12 |

|

|

|

C36000 |

|

|

0.18 |

|

|

|

|

|

|

C83600 |

0.003 |

|

0.15 |

|

0.50 |

0.03 |

|

0.003 |

0.040 |

C83800 |

0.003 |

|

0.15 |

|

0.50 |

0.02 |

|

0.003 |

0.040 |

C84200 |

0.003 |

|

0.20 |

|

0.40 |

0.03 |

|

0.003 |

0.040 |

C84400 |

0.003 |

|

0.20 |

|

0.50 |

0.01 |

|

0.003 |

0.040 |

C84500 |

0.003 |

|

0.20 |

|

0.50 |

0.01 |

|

0.003 |

0.040 |

C84800 |

0.003 |

|

0.20 |

|

0.50 |

0.01 |

|

0.003 |

0.040 |

C85200 |

0.003 |

|

|

|

|

0.01 |

|

|

0.025 |

C85400 |

0.175 |

|

0.35 |

|

0.50 |

|

|

0.025 |

|

C85700 |

0.300 |

|

0.35 |

|

0.50 |

|

|

|

|

C86400 |

1.000 |

|

1.20 |

0.8 |

0.50 |

|

|

|

|

C87500 |

0.250 |

|

|

|

|

|

|

4.0 |

|

C87800 |

0.075 |

0.03 |

0.08 |

0.075 |

0.10 |

0.01 |

|

4.0 |

0.025 |

C87850 |

|

|

0.05 |

0.05 |

|

0.12 |

|

3.0 |

|

C89510 |

0.003 |

|

0.10 |

|

0.05 |

0.03 |

0.55 |

0.003 |

0.040 |

C89520 |

0.003 |

|

0.10 |

|

0.05 |

0.03 |

0.95 |

0.003 |

0.040 |

C89530 |

0.005 |

|

0.15 |

|

0.50 |

0.03 |

0.20 |

0.005 |

|

C89535 |

0.005 |

|

0.15 |

|

0.65 |

0.20 |

|

0.005 |

|

C89540 |

0.350 |

|

0.25 |

|

0.50 |

|

0.05 |

|

|

C89550 |

0.400 |

|

0.25 |

|

0.50 |

0.05 |

0.05 |

0.125 |

0.025 |

C89836 |

0.003 |

|

0.18 |

|

0.45 |

0.03 |

|

0.003 |

0.040 |

C89844 |

0.003 |

|

0.15 |

|

0.50 |

0.03 |

|

0.003 |

0.040 |

Table 1b. Common names and typical uses |

|||

|

Name |

|

Uses |

| C22000 | Red brass | fittings, pumps | |

C23000 |

Cartridge brass | faucet tubes | |

C32000 |

Leaded red brass |

|

fittings |

C33000 |

Low leaded brass (Tube) |

|

plumbing accessories |

C33200 |

High leaded brass (Tube) |

|

plumbing accessories |

C34000 |

Medium leaded brass |

|

fittings |

C34500 |

|

|

valve stems, fittings |

C35000 |

Medium leaded brass |

|

meter parts, sink strainers |

C35300 |

High leaded brass |

|

fittings, faucet stems, faucet seats |

C35330 |

DZR brass |

|

fittings |

C35350 |

Leaded brass |

|

shafts for valves |

C36000 |

Free-cutting brass |

|

faucet stems, faucet seats, fittings |

C83600 |

Ounce metal |

|

faucets, fittings |

C83800 |

Hydraulic bronze |

|

plumbing fixtures |

C84200 |

|

|

tees, couplings, unions |

C84400 |

Valve metal |

|

fittings |

C84500 |

|

|

faucets, fittings |

C84800 |

Plumbing goods brass |

|

faucets, fittings |

C85200 |

Leaded yellow brass |

|

fittings |

C85400 |

No. 1 yellow brass |

|

plumbing parts |

C85700 |

Leaded yellow brass |

|

fittings, flanges |

C86400 |

manganese bronze |

|

fixtures |

C87500 |

copper silicon alloy |

|

fixtures |

C87800 |

cast silicon bronze |

|

plumbing parts |

C87850 |

copper silicon alloy |

|

faucets, fittings, water meter cases |

C89510 |

SeBiLOY I (EnviroBrass I) |

|

lead-free plumbing parts |

C89520 |

SeBiLOY II (EnviroBrass II) |

|

lead-free plumbing parts |

C89530 |

CuBiSe Alloy |

|

lead-free plumbing parts |

C89535 |

CuBi Alloy |

|

lead-free plumbing parts |

C89540 |

|

|

plumbing castings |

C89550 |

SeBiLOY III (EnviroBrass III) |

|

plumbing castings |

C89836 |

|

|

plumbing castings |

C89844 |

|

|

valves, fittings |

Source: Copper Development Authority